Introduction

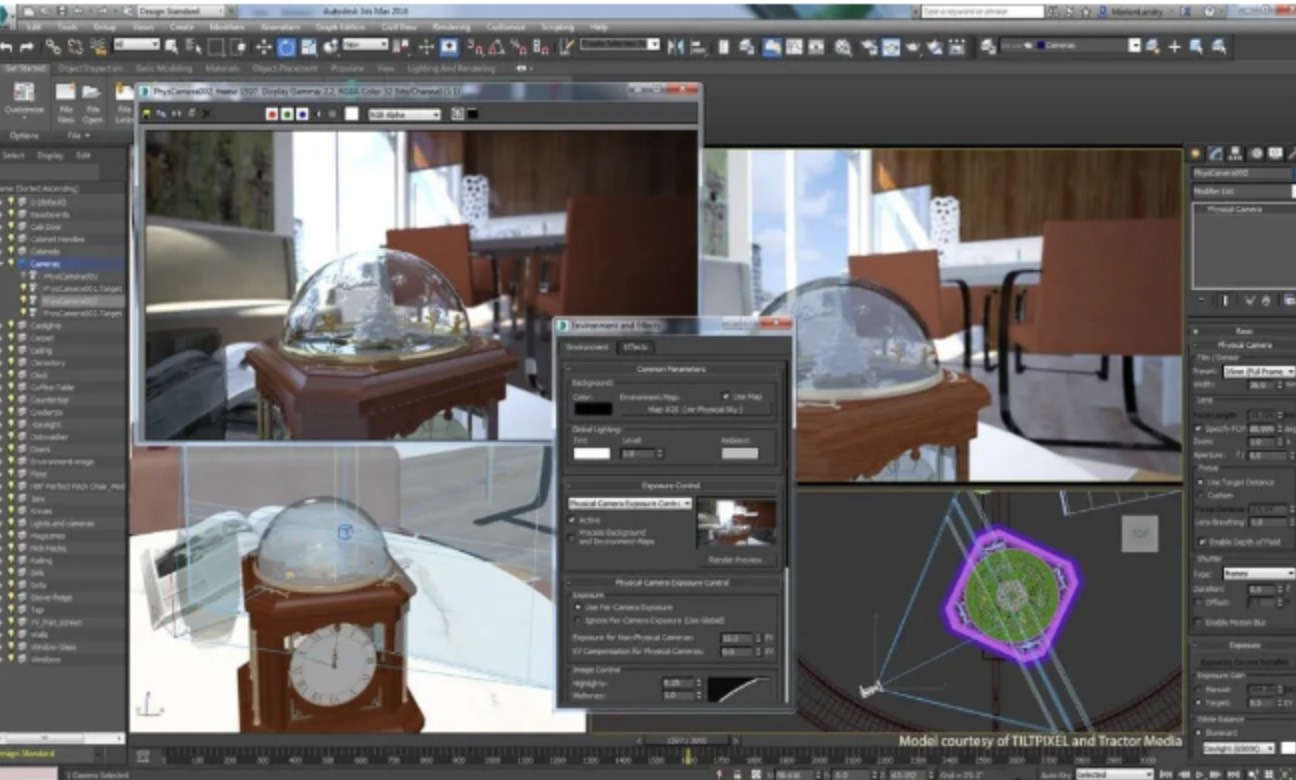

VGStudio and VGStudioMAX are software used to generate Volume models. This software supports input/output formats for most files, and can handle large capacity (1.5GB) data in both directions using a typical PC. By adjusting transparency and brightness, various stereoscopic images can be generated from the data

VGStudioMAX adds functions such as detection and partial output of models on the basis of image Visualization, and is widely used in medical and industrial fields. Additionally, if using the [Keyframer] software tool, animations can be made from stereo data.

Advantage

1гҖҒHigh precision - unique German technology enables accuracy to reach sub pixel level, which is below the hardware resolution of CT/MRI itself. For example, the measurement accuracy of three-dimensional wall thickness of bone structures can reach 1/3-1/4 of CT/MRT resolution.

2гҖҒMassive data processing -64 bit software has unlimited data processing capabilities with the improvement of hardware. With the support of excellent workstations, it can process tens to even hundreds of GB, terabytes of data, and 32-bit software can handle up to 3G data processing capabilities. The Egyptian mummy project sliced 60000 pieces, with an initial model data volume of 92G.

3гҖҒCT and MRI image fusion function - that is, using CT/MRI scans to obtain fusion data twice for the same object, and analyzing the same object based on the advantages of CT/MRI.

4гҖҒThe powerful multi object one scene function allows you to import multiple CT/MRI voxel models or even STL triangle models simultaneously in a single computational scenario, thus meeting your analysis needs.

5гҖҒPowerful geometric/intelligent/grayscale segmentation functions can divide the entire model into any sub models according to your needs, such as dividing the brain into brainstem/gray matter/white matter/skull Wait a minute.

6гҖҒOptimized STL extraction capability. You can control the accuracy between STL and original CT/MRI data and the smoothness of STL triangle data itself.

7гҖҒFully equipped image filtering capabilities to optimize your initial CT/MRI images.

8гҖҒUnique 3D film production ability and observation ability from any perspective - can enter the human body through a 3D simulation endoscope for observation from any perspective, and can also create 3D scientific education videos for courseware and animation.

VGStudio MAX Extended Features

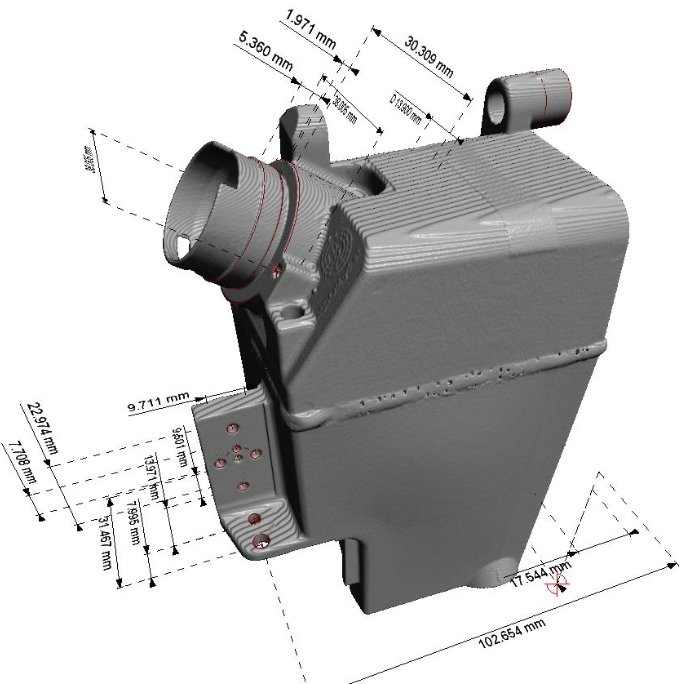

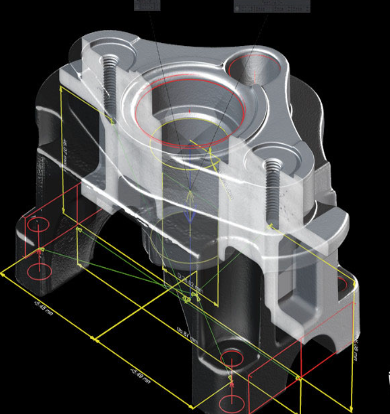

3D coordinate measurement module

Traditional methods prevent measurement tasks from being effectively completed and can only perform non-destructive testing, while VGStudio MAX transforms industrial CT scanning equipment into an efficient three-dimensional coordinate measurement system (CMS). This software has been specially extended for the application research of CT data, providing an efficient and intuitive user interface. In order to meet the high-precision requirements of CT data measurement, the optional 3D coordinate measurement (CM) module includes a unique advanced algorithm to accurately determine the actual surface with sub voxel accuracy.

The new features of this module significantly reduce the uncertainty of all measurement based on structural analysis, such as 3D coordinate measurement, design to object comparison, and wall thickness analysis. Different object positioning tools, such as "best fit", "3-2-1", "region of interest based localization (RPS)", and geometric structure based localization, are included in this module. The optional module for 3D coordinate measurement is a necessary condition for conducting all analyses and is executed in the specified 3D coordinate system.

The improved surface determination algorithm provides higher accuracy, especially for CT data with high contrast and High dynamic range, such as scanning data of multi material components. Combined with the newly enhanced coordinate measurement module, VGStudio MAX sets a new reference mark for the accuracy of CT measurement.

Design and physical comparison module

This module must be used in conjunction with the 3D coordinate measurement module.

The optional module for comparing design and physical objects can directly compare CT/3D pixel data with CAD or other CT/3D pixel data, which is more efficient than conventional methods.

Functional characteristics

в– Display the analysis results with color identification, which can analyze the entire object or the user specified "area of interest"

в– Geometric structure comparison can be directly performed on CT/3D pixel datasets without the need to convert 3D data into point clouds or STL data, thereby avoiding increased measurement uncertainty and loss of effective information

в– Powerful report export function, capable of exporting images and text in multiple formats (such as CSV, HTML, RTF, etc.)

New features in version 2.2

в– The design and actual comparison module can now use CAD data (STEP, IGES), grid data (STL), and volume data

в– More powerful reporting capabilities, especially for automatic detection functions

в– Supports native CAD data formats (such as STEP, IGES)

в– In the design/actual comparison module, various parameters can be used to specify tolerances, such as deviation (maximum, minimum, cumulative deviation)

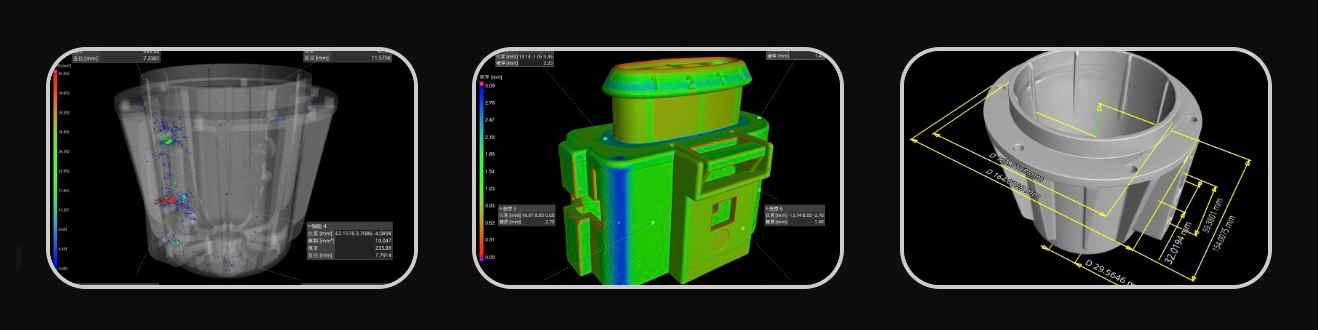

Wall thickness analysis module

The optional module for wall thickness analysis can automatically locate areas with insufficient area, excessive wall thickness, and large gaps directly on CT data/3D pixel datasets.

Functional characteristics

в– Display the analysis results with color identification

в– Analyze the entire object or user specified 'region of interest'

в– Directly process CT/Voxel data without the need to convert 3D data into point clouds or STL data

в– No CAD model required

в– Improved statistical analysis functionality

в– Powerful report export function, capable of exporting images and text in multiple formats (such as CSV, HTML, RTF, etc.)

в– If wall thickness analysis needs to be carried out in a precisely defined three-dimensional coordinate system, an optional three-dimensional coordinate measurement module must be purchased

New features in version 2.2

в– The wall thickness analysis module can now use CAD data (STEP, IGES), grid data (STL), and volume data

в– More powerful reporting capabilities, especially for automatic detection functions

в– In the wall thickness analysis module, various parameters can be used to specify tolerances, such as thickness (maximum, minimum, average, and deviation)

Porosity analysis

The pore/inclusion analysis module option allows for automatic detection of material discontinuities, such as pores, pores, and inclusions. CT based defect analysis has been widely used today, such as castings, plastic parts, and BGAs.

Functional characteristics

в– Automatically and quickly detect, analyze, and display defects

в– Detection of pores and inclusions

в– Defect detection can be performed on a complete dataset or within a user-defined area (region of interest)

в– Detected defects can be visualized by color coding based on the size of the quantity

в– Calculate various parameters for each defect (defect location, defect sphericity/density, defect size and geometric shape (volume, x-y-z coordinate size, projection area), nearest defect interval, distance from each defect to the reference surface (CAD or actual surface of the part)

в– Statistical defect Particle size analysis: overall percentage or porosity and defect volume histogram

в– Powerful report export function, capable of exporting images and text in multiple formats (such as CSV, HTML, RTF, etc.)

в– The data interface can output analysis results as simulation results and import them into MAGMASOFT ®

If the calculation of defects runs within the set coordinate system, a coordinate measurement module needs to be selected.

New porosity

In addition to 3D pore and inclusion analysis, the enhanced pore/inclusion analysis module option also supports non-destructive 2D defect analysis of castings, directly based on CT slice images, in accordance with VDG * specification P 201/VW 50097. This testing specification clearly defines the requirements for detecting the porosity of colorless metal castings.

Using the new features of VGStudio MAX, rectangular, circular, or triangular reference planes can be created from any selected orientation during CT scanning. Then determine the porosity and any tolerance within that plane. Determine the distance between the largest hole and the smallest standard hole within the entire cross-sectional image. Based on the defined pore categories (D, S, F, G) in the specification, this result enables you to perform automatic classification.

The pore analysis function developed according to the P 201 standard in VGStudio MAX holds great potential as it eliminates time-consuming sample preparation and microscopic photography. The analysis process can be saved as a template to quickly and repeatedly analyze all parts without any user intervention.

Using this module option, Volume Graphics has introduced microscope image analysis technology with sub pixel accuracy into industrial CT image analysis.

Fiber analysis

Fiber composite materials such as CFK and GKF play an important role in modern product design. This new analysis module provides powerful data analysis and solutions for all professionals in the field of fiber composite material applications. With the latest fiber analysis module from Volume Graphics, users can process data regardless of the size of the dataset. In overall or partial component analysis, modules can display individual fibers of very small material samples, as well as larger structures such as roving. This module can provide detailed information about the interior of the sample based on user needs and the scale of CT scanning.

The following parameters can be calculated:

в– Local fiber orientation

в– Local fiber content

в– Overall fiber orientation distribution

в– Overall fiber content

в– Single fiber segmentation and fiber parameter calculation (such as length, thickness, and orientation)

в– Overall fiber length distribution

в– Overall fiber thickness distribution

Display report analysis results in multiple ways, such as:

в– Local fiber orientation is displayed in color coding or vector, tensor, and streamline modes

в– The overall orientation distribution can be displayed through a histogram

в– Generate and output reports in various formats (CSV, HTML, RTF, etc.)

The new version of the fiber composite material analysis module has shortened the gap between real data and injection molding or mechanical simulation. The calculation parameters of actual components and material samples can be

Output in multiple formats (such as CSV, PATR AN), which can be directly compared with simulated data. Then, the obtained material parameters can be output and imported into the simulation task.

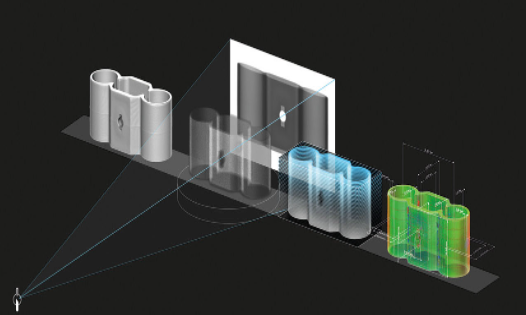

CT reconstruction module

By utilizing the options of the CT reconstruction module, Volume Graphics directly connects the CT scanner with the unique analytical capabilities and visualization of VGStudio MAX. This module has no special requirements for computer performance and graphics hardware. As long as it is within the processing capacity of computer hardware, the CT reconstruction module can fully utilize the latest GPU or multiprocessor/multi-core system to reconstruct datasets of any size. Users can independently choose to optimize image quality or computational performance.

Automatic scanning geometry correction

The CT reconstruction module has unique horizontal rotation center correction and axis automatic tilt correction (on the detector plane) functions, which can directly correct the data obtained from actual CT scans. Therefore, there is no need to pre scan the tested object. These corrections do not rely on CT scanning, and the instrument hardware itself can improve the quality of CT data. In addition, the CT reconstruction module uses Volume Graphics standard beam hardening correction or optional iterative artifact correction (IAR) function * (see below) to improve image quality.

Functional characteristics

в– Unmatched reconstructed image quality

в– Can provide users and hardware manufacturers with ultra fast GPU accelerated CT reconstruction results

в– Cone beam, fan beam, parallel beam, planar and spiral CT

в– Multiple automatic scanning geometric corrections

в– Beam hardening correction, iterative artifact elimination (IAR) * can be used for beam hardening correction

в– Unique interactive reconstruction preview

в– Artifact free region of interest (ROI) reconstruction

в– Offset scanning reconstruction

в– Can create VG projects

в– Performance mode can optimize the reconstruction time of large data sets CT scanner software integration and production process automation

The Software development kit (SDK) provided by Volume Graphics can be integrated on the control software of the CT scanning system. The integrated Software development kit can directly make VGStudio MAX call the scanning data set to start work in the way of VG engineering. In addition, it can execute macro commands, such as starting automatic detection tasks. Therefore, the Software development kit can build a fully automatic online detection system.

VGStudioMAX modern PCs and workstations are optimized using VGStudioMAX's Almost all functions to support multithreading, which significantly increases processing performance on multiprocessor/multi-core computers. Its rendering performance depends on the number of CPU cores, so we recommend using multi processor/multi core computers to maximize software performance. Since the total system memory requirements largely depend on the size of the user's typical dataset, we recommend that professional users run VGStudio MAX software in a 64 bit hardware and software environment, and the memory is at least twice the size of the largest dataset.